Coffee RO Conserv 75E

Coffee and Water RO Conserv 75E

This is the water of the future for coffee and soda .... dot ... The perfect water treatment for coffee and espresso machines and drinking water, this unique water system delivers the optimum lime-free water for coffee solutions where there must be 100% control over the water quality.

RO membrane removes all lime, salts, chlorides, minerals, micro plastic, ocher and except H 2 o then the water runs through active carbon filter and mineral filter which then adds the desired minerals to the water to achieve a perfect mixture for coffee production or soda "postmix ".

We have been working with espresso machines for almost 30 years and this solution is ultimately the best we have seen to date ,,, solves our problems with lime and penetration as well as neotral Ph challenges. This method is applied to all Starbox, Burger King Mc Donalds so that the same water profile is achieved worldwide. In short, you remove everything from the water: lime - salt pesticides micro plastic and other unwanted in the water and then build up the water according to your wishes .... Exembel: Coffee or soda at Burger King in Inside where there is not the right water profile for coffee or soda due to chlorine - impure water .... everything is removed so that only H2o is added then what we want.

All filters and membranes are changed at least once a year.

RO Everpure Conserv 75E Reverse osmosis is a solution that brings benefits to coffee programs. It combines an activated carbon filter, lime-free water, and no clorides (salts in the water). To this end, the right mix is created to create the important balance of minerals to prevent both corrosion and liming, which distinguishes it from conventional RO systems. In short, it does not clog but completely without the fermentation of metals, which we have not seen before on normal lime filters for coffee and espresso machines.

Come by for a talk about the perfect water for your business

It is a reliable, easy to install and easy-to-operate solution that requires cartridge replacement only once a year.

The system helps users meet the foodservice equipment manufacturer's requirements for water specification, maintenance of warranty compliance, reduction of early warranty assumptions, increased longevity, and customer satisfaction.

- Daily production rate: 50.51 gpd (191.20 lpd)

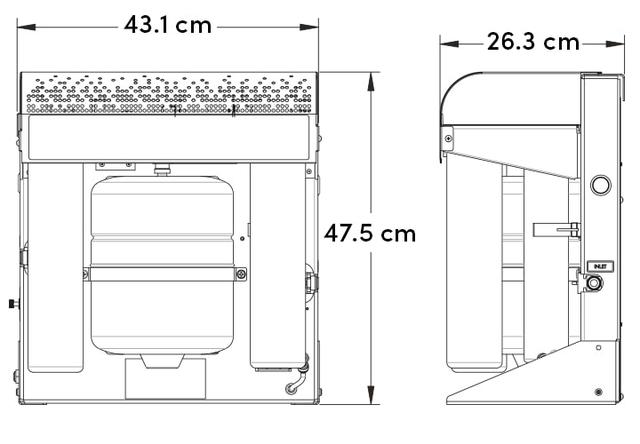

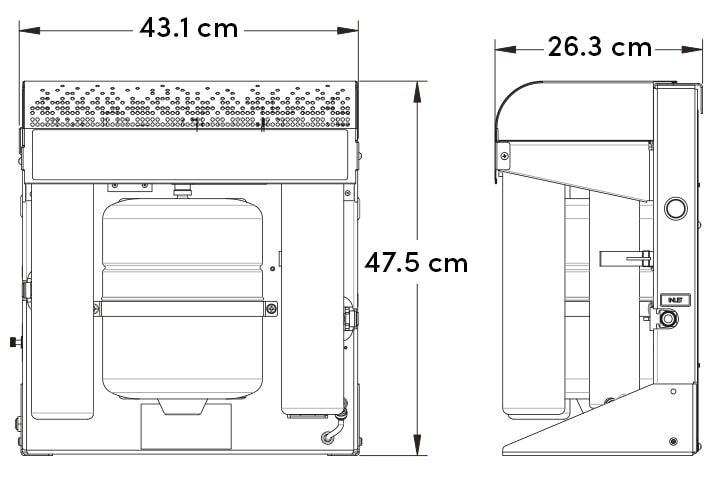

- Total dimensions: 18.69 "H x 16.97" W x 10.37 "D (47.5 cm x 43.1 cm x 26 cm)

- Inlet / outlet connections: 3/8 "OD John Guest ® mounting

- Wastewater pipeline plant: 1/4 "OD John Guest installation

- Water supply: 0.5 gpm @ 50 - 85 psi (1.9 L @ 3.4 - 5.8 bar)

- Pressure requirements: 40-85 psi (2.7 - 5.8 bar), non-shock

- Inlet temperature: 32-100 ° F (0 - 37.7 ° C)

- Inlet TDS: max. 1000 ppm

- Operating weight: 53 kg (24.04 kg)

- Waste water production: 14-20 gpd @ 60 psig, 77 ° F (53-75 lpd @ 414 kPa, 25 ° C)

- The drainage pipeline capacity: 0.05 gpm (200 ml / m) to open the atmosphere

- Storage Tank Capacity: 2 gallon tank; Efficient / usable capacity 1 gallon (3.8 l)

- Electric: 100-240VAC / 50-60Hz switchable power supply

There is no reviews yet. Be the first to write us your opinion